About Us

Phone: (217) 625 - 2771

Fax: (217) 625 - 2701

Address: 512 6th Street

Pawnee, IL 62558

Hours of Operation:

Monday - Friday 6:30am - 4:00pm

NOTE: We are available on Saturdays by appointment only. Please call the office to schedule your appointment at 217-625-2771

Professional Services

Need help with a material list? Just bring in your blueprints, plans, drawings, etc., and we can help you get started. If you already have a material list, just bring it in and we can help you with pricing and assistance.

We provide a ladder conveyor with all shingle orders free of charge. ( up to 24')

Insulation blowers can be rented with all blown cellulose purchases.

Locks can be re-keyed. (Schlage)

Need duplicate keys? Most keys can be cut on site.

.

About Low-E Insulation

Beyond “R” Values:

Reduce Energy Costs Now!

Retail facilities must provide a comfortable and productive environment for employees and customers. A large part of this comfort level involves the temperature inside the building. If it is too hot or too cold, it can reduce productivity and drive away customers.

In an attempt to maintain cozy temperatures, more than half of the energy used in the typical retail facility is for heating and cooling. When most retailers try to boost energy efficiency and reduce utility costs, they focus on conventional methods. This includes lowering thermostat settings and replacing or performing maintenance on the heating and cooling system. While these methods can help to some degree, they are not the most efficient strategy.

The key to maintaining a comfortable temperature in any facility is to reduce the heat transfer out of the building in winter and into the building in summer. This can best be accomplished with the proper insulation, installed correctly. To determine the most appropriate type of insulation, it is important to first understand the different types of heat.

Radiation (Radiant Heat)

Heat moves through walls, roofs and ceilings by radiation (radiant heat), conduction and convection, but radiation is the dominant way. Radiation is the transfer of heat by infrared radiation across an air space, such as in an attic on a hot day. Conduction is the transfer of heat between two contacting surfaces. Convection is the transfer of heat by the flow of air or fluid.

Radiant heat transfer is the most significant cause of unwanted heat gain or loss. According to industry sources, radiant heat is responsible for up to 93 percent of summer heat gain, and 75 percent of winter heat loss. Unfortunately, regular mass insulation, such as fiberglass and cellulose, can only stop 10 to 20 percent of this heat, and the remaining amount of radiant heat passes through. This leads to higher energy bills, as heating and cooling systems work to keep up with the huge loss and gain.

Fiberglass and cellulose are effective in preventing heat transfer by conduction but have virtually no effect on radiant heat. In fact, they actually absorb radiant heat and transfer it into buildings. Between 80 and 90 percent of the radiant heat striking fiberglass will pass through or be “emitted”. The only type of insulation that is effective against radiant heat is reflective insulation.

Reflective Insulation

“Reflective insulation utilizes the same technology NASA uses in space shuttles and spacesuits, and it performs the same function - it reflects radiant heat back toward the heat source,” explains Bobby Ratcliff, at Global Energy Technology, in Houma LA. “On hot days it reflects heat away from the building and on cold days it keeps heat inside the building.”

Global Energy Technology provides and installs reflective insulation in commercial, residential and industrial projects, for both new construction and retrofit applications. Projects have included Wal-Mart stores and distribution centers as well as other department stores, shopping malls and retail facilities.

“Basically, reflective insulation consists of an inert material sandwiched between reflective foil,” says Ratcliff. “For example, Low-E Insulation is manufactured using a 1/4” polyethylene foam core with scrim reinforced double-sided aluminum facings. It can be used in all facets of the building industry where conventional insulation is used. It can be used alone or in conjunction with mass insulation. The product is very easy to install and can dramatically reduce energy bills in any climate.”

Low-E, the number one selling reflective insulation in the country, is manufactured by Environmentally Safe Products (ESP), Inc., based in New Oxford PA. The company produces a complete line of energy-efficient products for home and commercial insulation.

“Reflective insulation reflects radiant heat energy instead of absorbing it, which is critical for energy savings and efficiency,” states Chuck Hockensmith, Technical Training Manager at ESP, Inc. “After all; up to 93 percent of heat gain in summer is radiant. During winter months, radiant heat accounts for 50-75 percent of heat loss through ceilings/roofs and 65-80 percent of heat loss through walls.”

Hockensmith points out that, “The primary function of reflective insulation is to reduce radiant heat transfer across open spaces. This insulation reflects most of the radiation striking its surface and emits very little of the heat conducted through it. It can block 97 percent of all radiant heat entering or leaving a building. It also blocks air (convection heat transfer) and humidity from passing through and getting inside. This unique ability allows your business to stay more comfortable all year long.”

Unlike mass insulation, reflective insulation is unaffected by humidity and continues to perform at a consistent level in any humidity. It will not absorb moistures and performs equally well in any climate without any loss in performance. Since the insulation is made from closed cell polyethylene and a pure aluminum facing, it also serves as a vapor barrier.

“Reflective insulation is designed for installation between or over framing members in walls, ceilings, and floors, for new construction and retrofit applications,” Ratcliff comments. “It installs easily with razor knife, tape measure, staple gun and foil tape. The material maintains a consistent thermal break and it seals tightly around fasteners.”

Commercial grade Low-E is 1/4” thick and available in 4’, 5’ and 6’ rolls, in standard lengths of 125’, 100’ or 84’. The standard 500 square foot rolls weigh less than 30 lbs. It is available with or without extended staple flange, and available with a white facing on one side. Custom lengths are available depending on quantity ordered.

“A significant amount of heat loss and gain occurs through walls of buildings,” says Ratcliff. “In warmer climates reflective insulation installed properly in walls can greatly reduce the amount of incoming and outgoing radiant heat.”

Ratcliff states that, “Reflective insulation should also be installed in attics and roofing systems. This keeps out most of the summer heat, which lowers air conditioner use. Plus, it cuts down on winter heat loss. Since reflective insulation has a low emittance, it radiates only about 3 percent of radiant heat. By installing reflective insulation on the attic floor, it reduces the amount of heat lost through the existing mass insulation.”

Reflective insulation is different from conventional mass insulation in several ways:

· It does not have significant mass to absorb and retain heat;

· It has lower moisture transfer and absorption rates;

· The change in thermal performance due to compaction or moisture absorption, a common concern with mass insulation, is not an issue with reflective insulation.

· It has very low emittance values or “E” values.

“E” and “R” Values

The “R” value is a measure of insulation’s resistance to heat flow. Many building owners are losing money with insulation products that rely solely on R value as the principal measurement of performance. Supposedly, the higher the R value the more effective the insulation. For several reasons, however, this may not be entirely accurate.

First, R value primarily measures insulation’s ability to resist heat flow by conduction, which is only seven percent of the total heat transfer equation. Radiant heat is the primary cause of heat gain in summer and heat loss in winter.

Second, although fiberglass and cellulose have high R values they are not effective toward radiant heat.

Third, mass insulation is seriously affected by changes in humidity and moisture levels. According to the HVAC Manual, “A 1½ percent change in the moisture content of fiberglass insulation results in a 36 percent decrease in performance.” Reflective insulation is not affected by humidity or moisture.

Reflective insulation actually has more R value per inch of thickness than any other insulation. It is also rated for summer and winter. However, reflective insulation is measured in emittance or “E” values ranging from 0 to 1. The lower E value, the better the performance will be.

“Mass insulation products, such as fiberglass, foam and cellulose, have E values of 0.70 to 0.90,” says Ratcliff. “Low-E has an E value of 0.03. Therefore, it is superior to other types of insulating materials in reducing heat flow by radiation. It can also trap air, which reduces heat flow by convection. So it is effective against two types of heat transfer.”

Ratcliff adds that, “Reflective insulation lowers the attic temperature in the middle of summer by 45 to 50 degrees. It works on the same principle as an old-fashioned glass-lined thermos bottle, by reflecting radiant heat. It keeps the radiant heat from entering the building.”

Cost-Effective

Reflective insulation reduces the heat transfer through the envelope of a building, providing a much more comfortable and productive environment. Even though the technology has been around for over 40 years, it has only recently become an important part of energy-saving efforts. Reflective insulation makes increased energy efficiency and savings easy and inexpensive.

“When compared to cellulose or fiberglass, reflective foil has several major benefits,” says Ratcliff. “Low-E has a Class A, Class 1 Fire Rating. It is non-toxic, non-carcinogenic, and contains no substances that will out-gas. It does not irritate the skin, eyes, or throat and requires no special handling or clothing to install. Plus, it offers superior thermal performance and improves the performance of other insulation systems.”

Unlike some insulation, reflective insulation is insect resistant and does not promote the nesting of rodents. It is an excellent vapor barrier, and reduces condensation. In addition, the effects of moisture condensation and air movement are minimized, which results in lower maintenance costs and increased longevity of the building structure.

“Installing reflective insulation is not just a way to reduce energy costs, it quickly pays for itself,” states Ratcliff. “In the typical commercial or retail building, it usually takes less than one year to recoup your money just on productivity savings. I’ve seen people cut their energy consumption by as much as 45 percent compared to buildings with just fiberglass or cellulose insulation. In most cases, you can expect a return on your reflective insulation purchase within one to three years.”

The bottom line is that reflective insulation works. It saves time and money. Mass insulation can do little to keep a building from getting hot, but reflective insulation can make an otherwise unbearable environment a pleasant place to work.

The End

For more information about reflective insulation or Low-E, contact Environmentally Safe Products at 800-289-5693 or www.low-e.com.

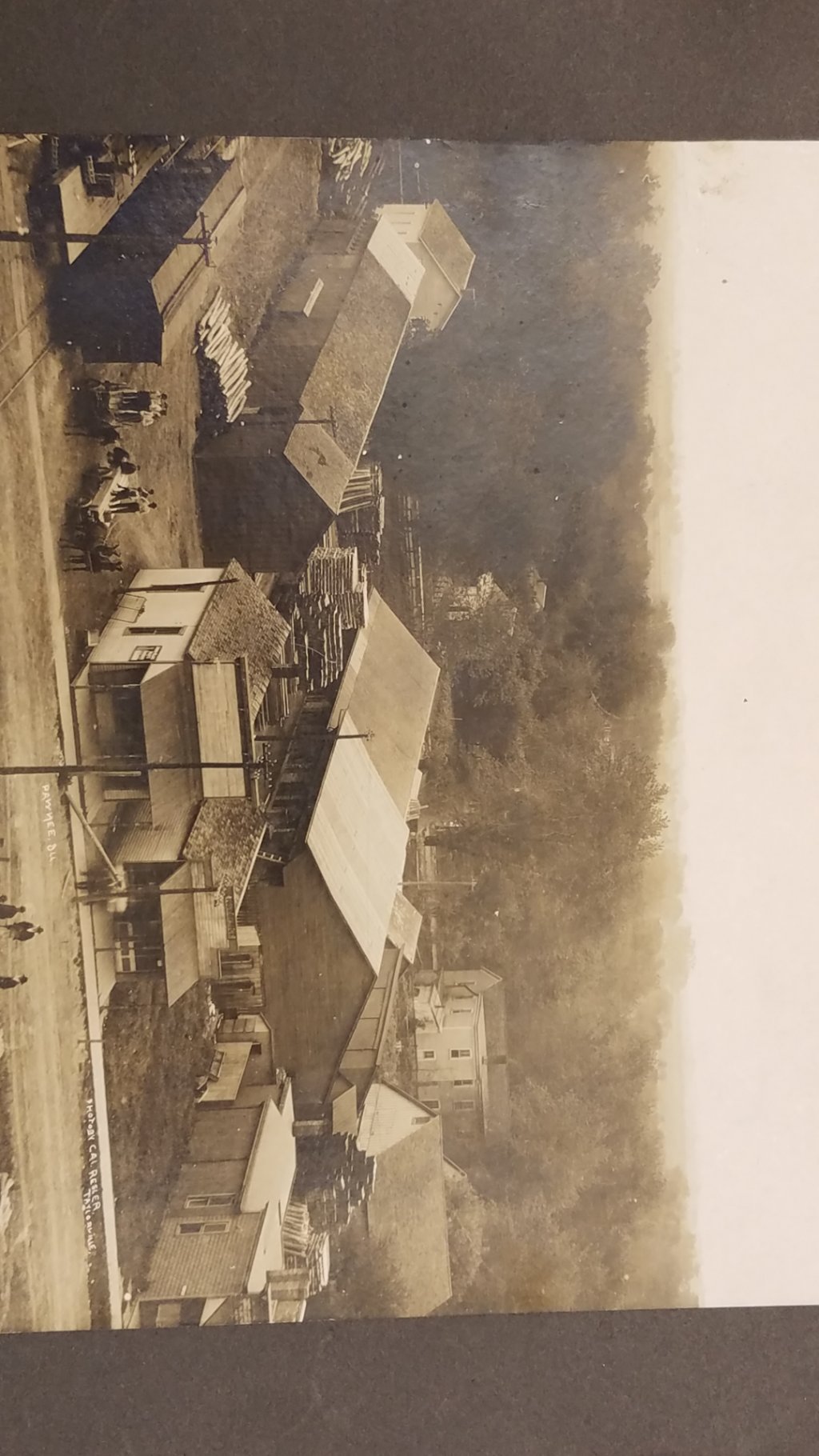

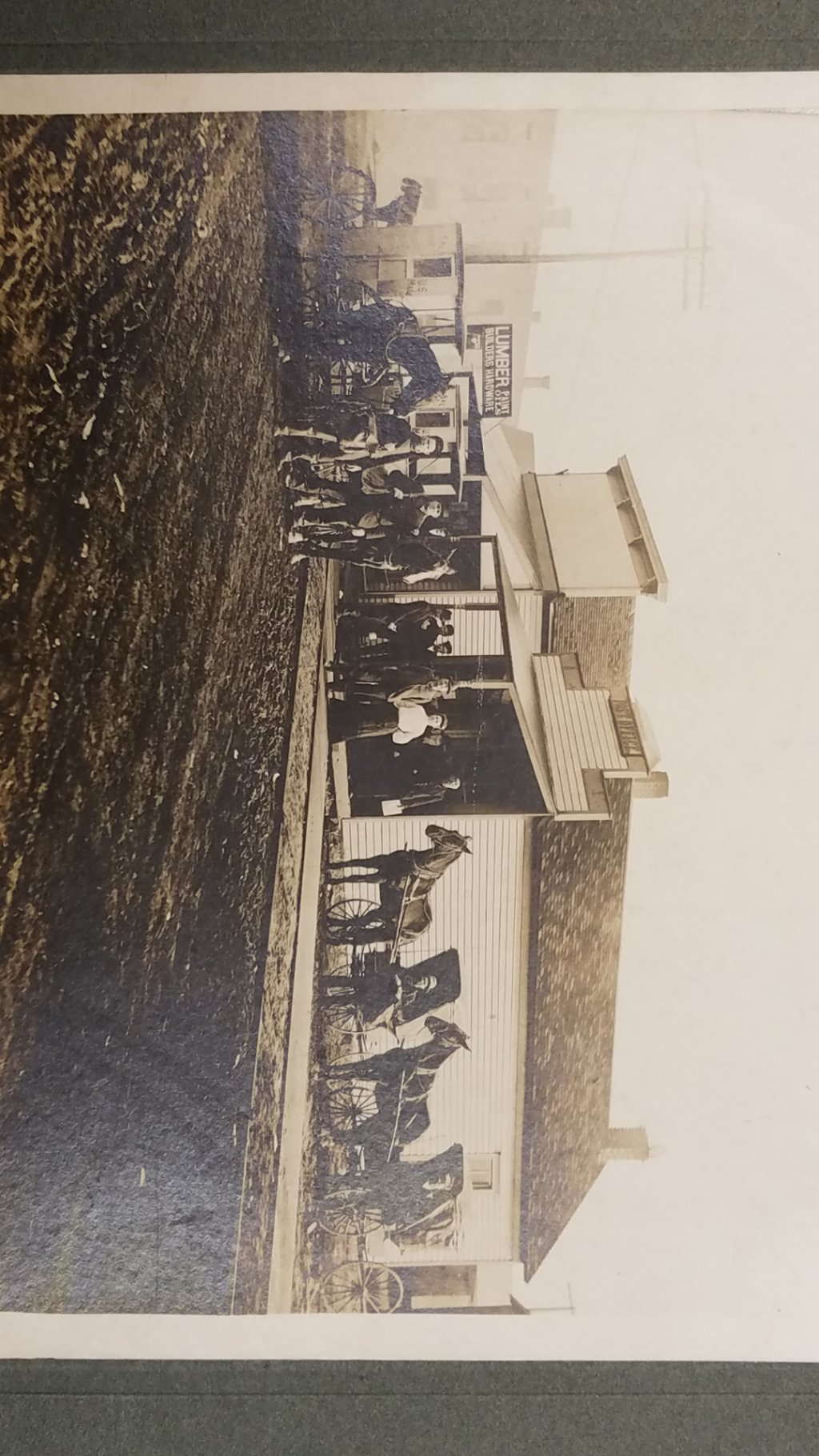

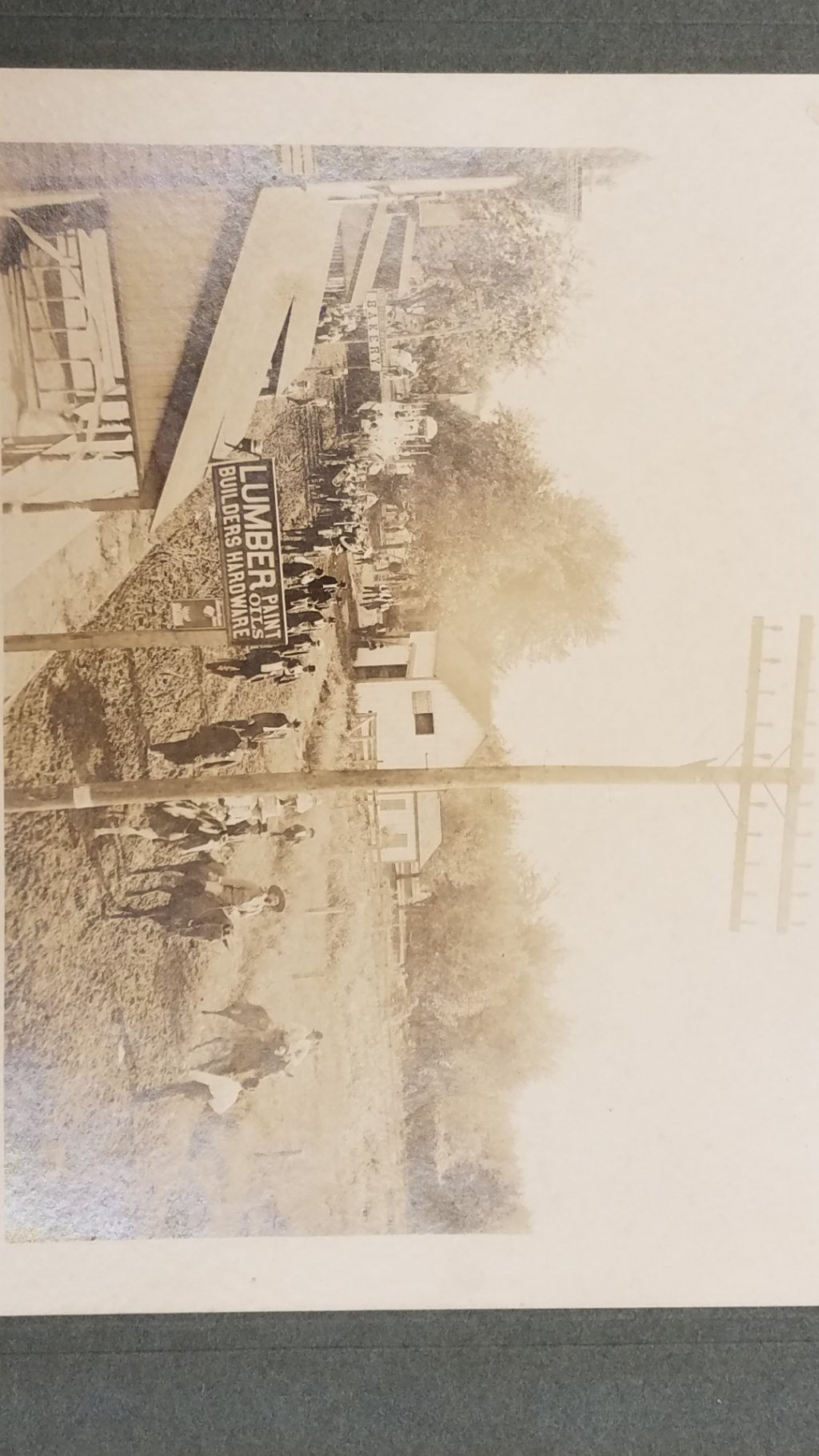

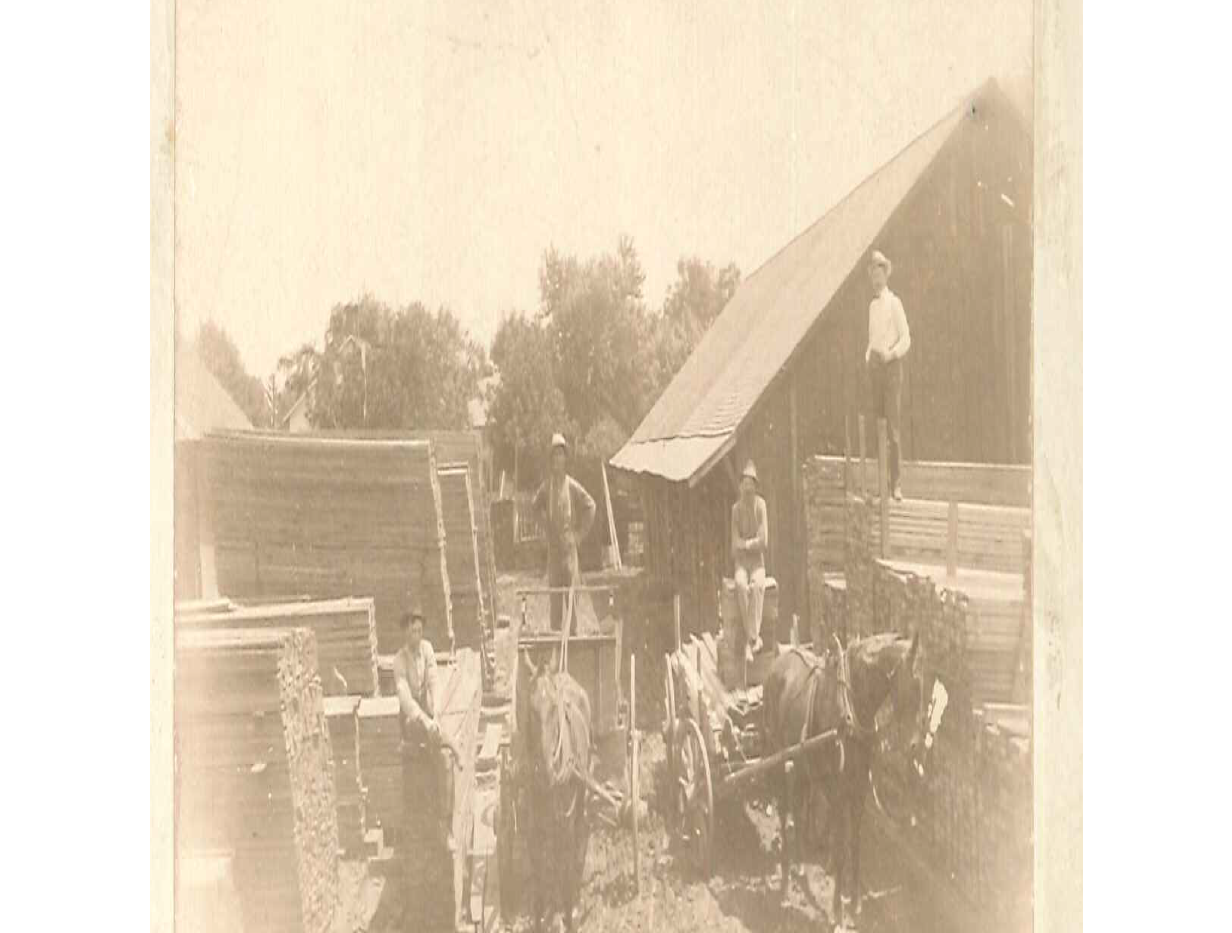

Pictures